We consider Helium Leak Detection Services (HLD) as the most advanced, coming from the scientific community leak diagnostic technology to detect, pinpoint and quantify leaks at precision (the gas leakage amounts) in a range of 0.1 mbar x L x sec-1, using mass spectrometry methods to identify the presence of Helium at a molecular level

All our Helium Leak Detection Services & Diagnostic test procedures to be performed strictly in accordance with the ASME BPVC Code Section V, Article 10 guidelines, ASTM E499 Standard Industrial Practices and ISO 20484 Standards; also, any other special requirements and industrial standards would also be considerable. Helium / Hydrogen leak Detection technology is also the most efficient way to detect leaks in Hydrogen-handling systems and facilities.

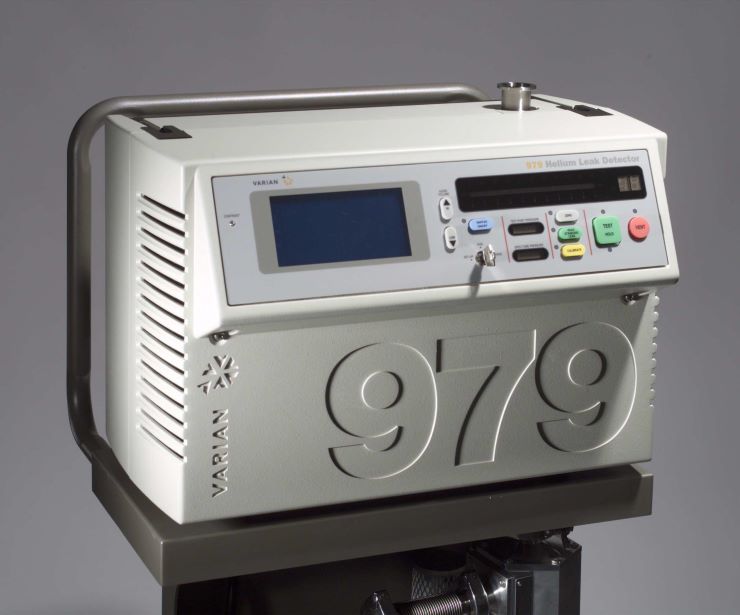

Keeping the highest quality standards, for the 24/7 field Helium Leak Detection Services & Diagnostic / NDT masspectrometry we propose the best in class Helium Leak detectors PHOENIX L300 by Leybold GmbH and Model 979 by Agilent (Varian) Technologies, capable of detecting, locating and quantifying leaks in a range of 10E-12 mbarxL/sec (scc/sec) in a vacuum mode and 10E-7 mbarxL/sec (scc/sec) in a sniffer mode.

Along with the Helium Leak Detectors, we also consider the NGD268 Portable Combustible Gas Leak Detector, utilizing a hot-wire semi-conductor sensor at the detected gas sensitivity of < 50ppm to identify the presence of Hydrogen, hydrocarbon gases, Isopropyl alcohol, halogenation hydrocarbons, ketones and other compounds such as gasoline, industrial solvents, lacquer, refrigerants, ammonia, acetic acid, etc.,

Note: we DO NOT offer/ provide any inspections of commercial (household) natural gas systems, nor refrigerant-containing equipment and appliances, as well as no one of the listed above technique, technologies and instrumentation can be considered as lifesaving measures or lifesaving devises. .

The Thermographic Imaging by the SC240M IR thermal imager reveals the source of problems in case of maintenance and troubleshooting of industrial equipment, using seven multiple color palettes and optical, fusion, and PIP (picture in picture) 4-image modes Thermographic imaging technologies are absolutely critical for identifying/diagnostic of leaks in all types of heat pumps; especially for locating and quantifying leaks in the ground source heat pump lines.